There was no shortage of ‘oohs’ and ‘ahhs’ in Northampton at ELRIG’s recent Robotics and Automation 2014 Conference (1st July), hosted by Festo. From an impressive selection of companies in the exhibition room to fascinating talks on the evolution of high throughput screening, computer active learning and the future of computer user interfaces (UIs), people were kept on the edges of their seats; hidden beneath a few of which were even tokens for a fluidic-muscle driven F1 racing simulator race contest! Oooh! Read on for a few of our favourite highlights from the event.

Robots and nature

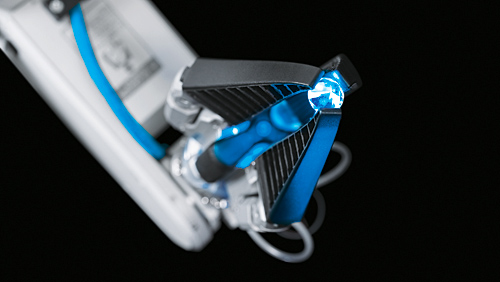

Festo’s Nigel Dawson kicked off the conference with an impressive selection of the robotic ingenuity we’ve come to expect from the Festo team. We were also introduced to the Bionic Learning Network, an open source research network linking numerous universities, institutes, companies and private inventors, allowing ideas and technology about biomimetics and biomechatronics to be freely shared and developed. Next we were allowed to indulge our inner geeks, looking at videos of the biomimetic robots themselves. A pervasive theme was something termed ‘autonomous collaboration’. In the development of robotic penguins for example, individual robots propel themselves through the water (or the air!) completely autonomously but also collaboratively: groups of these will swim together without colliding into each other thanks to a 3D sonar system, much like that used by dolphins in the wild. This spatial awareness was beautifully demonstrated by the eMotion Spheres: eight helium-filled spheres driven by propellers capable of precise, collaborative, responsive movement (within 10mm of each other), as well as autonomous charging when their power sources began to dwindle. Other exciting inventions included the SmartBird – the first robotic bird to achieve autonomous flight, i.e. without any propulsion system; the BionicOpter – a robotic dragonfly with a 700 mm wingspan yet weighting a mere 185 g, capable of mimicking the insect’s complex flight pattern and beating its four independent wings 20 times a second; and of course, the Bionic Handling system, capable of delicate and versatile mechanical gripping.

When asked about the practical applications of some of these, Nigel Dawson explained that it was much more about what they learnt during a project’s three years of production, in terms of technical innovation, rather than the development of a commercial end product. I like to think that, if the question is ‘Why build these amazing robots?’, then a fair answer is simply ‘Why not?!’ More seriously, many of the innovations underpinning current and future products evolved out of these biomimetic projects. For example, the versatile handling system, which can tightly grip objects of a variety of shapes without damaging them, borrows heavily from design principles unexpectedly learnt when replicating the structure and functions of a fish’s tail.

Laboratory automation and silico scientists

The increasing sophistication of automated system for improving the speed, accuracy and reproducibility of lab processes, such as the generation of antibodies or the screening of vast numbers of compounds, was a trend discussed by several speakers. Roger Norwood, formerly of Astra Zeneca but now at Unilever, took us on an enlightening journey through the evolution of automated systems on an industrial scale over the past couple of decades. It was genuinely astonishing to see just how far technology has moved along in a relatively short period of time and how the required skill set has both grown and diversified into an eclectic mix of science, engineering and project management; lots of people had to get very smart, very quickly, in this area! It was also interesting to note that, with the rapidly growing size of sample sets and work cells, companies like Unilever are still trying to work in a ‘green-friendly’ way, increasing efficiency while also keeping environmental impact to a minimum.

Simon Tickle (UCB) gave us a great insight into the needs of those working in therapeutic antibody discovery and how automation is continuing to help drive the ongoing evolution of screening programs. For example, in his laboratory, this has led to the creation of a complex and integrated screening system combining filling, screening and hit-picking work cells, all under the control of app-like software on touch screen displays. The UCB technology is now being opened up to academics and research groups that would like to make use of the fully automated, £3 million, discovery platform. The robots already have their own IP addresses and email accounts for off-site interaction – it won’t be long before they have twitter accounts, posting about, ‘Ten thousand samples, DONE! Totally getting Automated Employee of the Month! #LabLife’.

Later on, Ross King (University of Manchester) walked us through the development of computers capable of conducting science; not just robots eliminating some of the repetitive aspects of bench work, but an artificial intelligence (AI) system capable of designing the hypothesis, executing the experiment, interpreting the results and moving on to repeat and iterate the process – a ‘Robot Scientist’.

The first iteration of this robot scientist, named Adam, was the first machine to have discovered novel scientific knowledge. The next model, Eve, is being developed to automate drug discovery (assay design, screening, hit confirmation etc.) and will be focussing ‘her’ attention on tropical diseases. This amazing AI makes use of first-order predicate logic (rather than Boolean fingerprinting) to analyse the quantitative structural activity relationships (QSARs) of potential chemical candidates. This really felt like listening to something from a sci-fi film – robots automating tasks is one thing, but designing and testing hypotheses? Wow! Go science (robots)!

A new role for human scientists

This level of automation raised two great points in my opinion. Firstly, that the need for an integrated, multidisciplinary approach to science is required now more than ever. Many of the developments seen at the conference were a result of biologists talking with engineers, who were talking with computer scientists and project managers, with everyone talking with end-users. Novel perspectives in a collaborative setting will invariably breed innovation.

Secondly, many will worry that robots – especially those with an advanced AI – will make scientists redundant, but I disagree. This level of automation gives scientists the opportunity to really do what scientists do best: thinking about their data and making connections between seemingly disparate results to take science forward. Vast amounts of bench work is taken up with repetitive, ‘thoughtless’ tasks. If an automated system can work to eliminate that, the scientist is free to really consider the data generated and to formulate new ideas and approaches in a more focused manner than ever before. Rather than make us redundant, robotics will allows us to move into a new era of scientific discovery, allowing us to do what we do best: drive innovation.

F1 simulation competitions are a serious business!